Forsyth County, GA – In a move towards more environmentally friendly transportation, Forsyth County Schools, a district northeast of Atlanta, is considering a significant shift to propane-powered buses for the upcoming school year. During the recent work session on September 12, Director of Transportation, Mike Satterfield, presented this idea to the Forsyth County Board of… Continue reading Forsyth County Schools in GA Explore Cleaner, Cost-Efficient Propane Buses

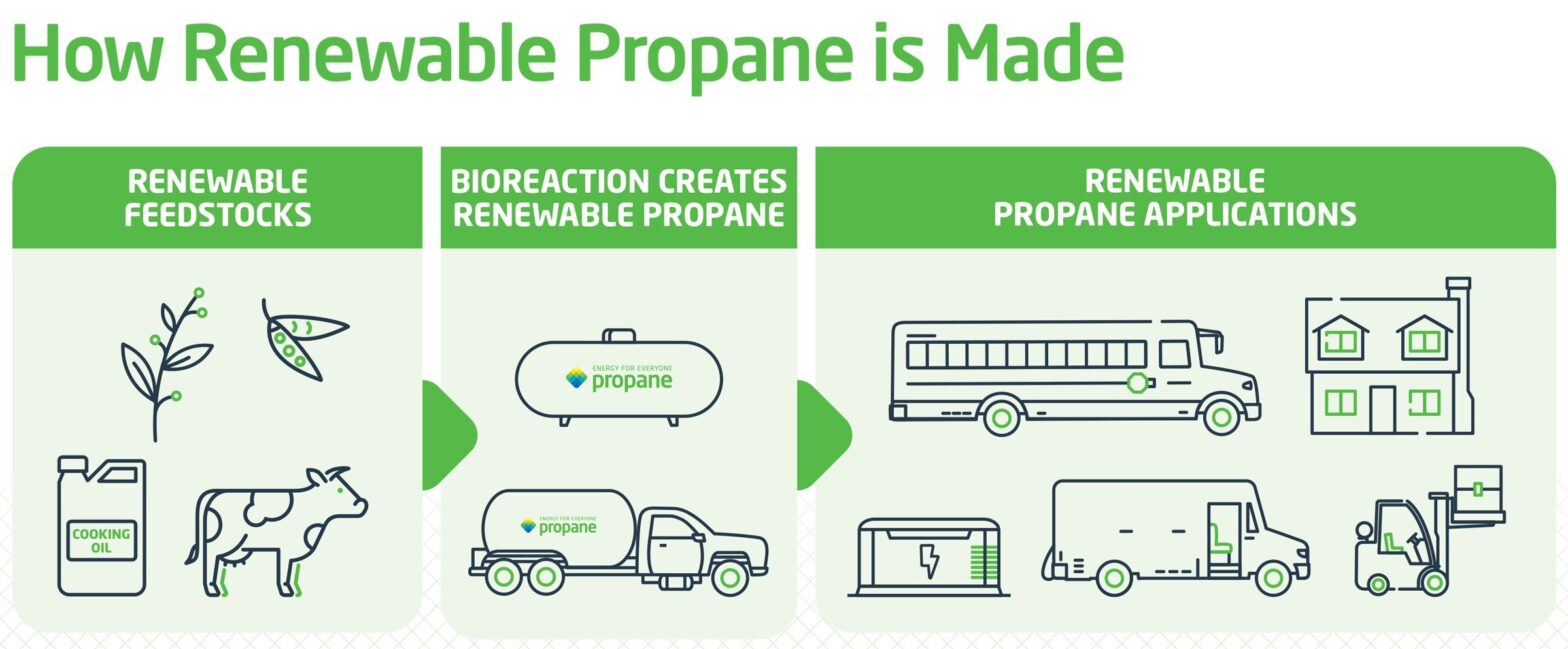

Forsyth County, GA – In a move towards more environmentally friendly transportation, Forsyth County Schools, a district northeast of Atlanta, is considering a significant shift to propane-powered buses for the upcoming school year.

During the recent work session on September 12, Director of Transportation, Mike Satterfield, presented this idea to the Forsyth County Board of Education. He emphasized that transitioning to propane buses could help reduce fuel emissions and lead to substantial transportation cost savings.

Satterfield outlined the compelling reasons for Forsyth County Schools to contemplate this transition, focusing on financial and environmental benefits. He explained, “The reason we feel this is an important opportunity for Forsyth County Schools to consider is a reduction in cost for the bus fleet, both in terms of fuel and maintenance. And then an increase in the environmental emissions compliance and a reduction in overall environmental compliance cost that we currently have with our diesel-powered bus fleet.”

Satterfield consulted propane bus vendors to gather data on the cost and emissions differences between propane and diesel and discussed the matter with leaders from other metro Atlanta school districts already operating propane buses.

Breaking Down the Savings

Propane’s appeal becomes evident when comparing fuel costs. Satterfield revealed that propane is priced at $1.67 per gallon, significantly lower than the average diesel cost of $3.71 per gallon. However, propane buses consume fuel at a faster rate. Satterfield clarified, “With the energy consumption and the energy produced by propane, you have to purchase about 60% more propane fuel than you would diesel to get the same mileage out of your bus.”

Despite this higher consumption rate, transitioning part of the 473-bus fleet to propane could lead to substantial fuel savings. Last school year, the district spent over $2.7 million on diesel fuel, averaging about $5,800 per bus. Had these buses been propane-powered, the cost would have been approximately $4,300 per bus, potentially saving more than $700,000.

Additionally, Satterfield highlighted available alternative fuel tax credits. These credits include a federal government incentive of 37 cents per gallon of propane used, along with an infrastructure tax credit. The latter covers 30% of the cost, up to $30,000 per property, for propane fueling equipment installed by December 2024.

Considering these tax credits, Satterfield estimated potential additional savings of $450,000 when considering last year’s fuel expenses.

Propane buses also offer lower maintenance costs compared to diesel buses. Diesel vehicles typically incur higher maintenance expenses, including parts and additives like diesel exhaust fluid, which propane buses do not require.

Infrastructure Investment

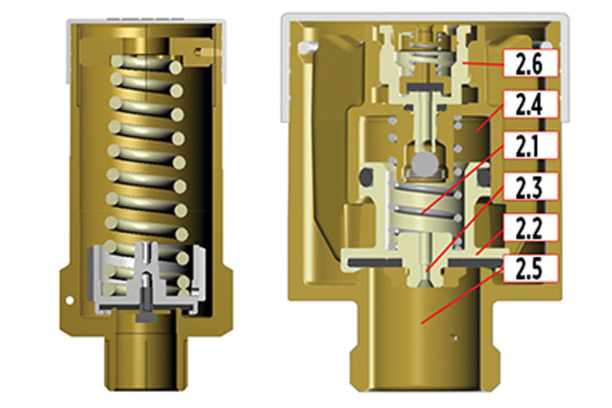

The primary investment required for transitioning to propane-powered buses is infrastructure-related. Establishing a propane tank and dispenser filling station in the county would cost approximately $250,000. However, Satterfield noted that the district plans to select just one such station, with bus vendors potentially assisting with initial costs.

Satterfield also clarified that the cost of each propane bus is roughly equivalent to a diesel-fueled bus. Furthermore, the state is offering a $12,000 rebate per propane bus purchased by school systems until June 2025.

Propane vs. Diesel

Board members raised questions about the performance and safety of propane-powered buses compared to the existing diesel fleet. Satterfield shared that when they initially explored propane buses in 2017, the engines did not match the power of diesel engines. However, significant improvements have been made, and now there’s “no significant difference in the drive between a diesel and a propane-powered bus.”

Regarding safety, Satterfield asserted that conversations with vendors and other metro Atlanta counties revealed no additional protection or fire risks associated with propane-powered buses compared to diesel buses.

The most notable difference lies in the environmental impact. A 2018 West Virginia University study found that propane buses reduced nitrous oxide emissions by about 96% compared to diesel buses. There was also an 80% reduction in hydrocarbons and a 100% reduction in particulate matter emissions. This reduction in emissions, as noted in a 2019 article in the Economics of Education Review, could positively impact students’ health and academic performance.

Next Steps

The research into propane-powered buses has been ongoing for approximately nine months, with Satterfield and his team studying other regional school districts that have adopted these buses.

The transition to propane will not be immediate or complete. Instead, the district plans to continue researching this alternative fuel source. However, if the board approves the plan, transitioning part of the school bus fleet to propane could begin this school year by constructing a propane fuel tank and dispensing station.

The board and district leaders are currently reviewing the proposal, hoping to implement the changes by the start of the next school year if approved.

Considering the challenges posed by industry wide driver shortages and the extended time required for emergency driver training, marketers must plan with agriculture customers. Encouraging early tank fills ensures farmers have an adequate propane supply to power their farms throughout the harvest and winter seasons, while also benefiting from potential cost savings.

Considering the challenges posed by industry wide driver shortages and the extended time required for emergency driver training, marketers must plan with agriculture customers. Encouraging early tank fills ensures farmers have an adequate propane supply to power their farms throughout the harvest and winter seasons, while also benefiting from potential cost savings.

Propane autogas offers the lowest cost of ownership compared to other fuel types. ThompsonGas achieves a 60% lower cost per mile for its propane vehicles than diesel-powered models.With simplified maintenance requirements, the company estimates that its propane vehicles will last between 250,000 and 300,000 miles.

Propane autogas offers the lowest cost of ownership compared to other fuel types. ThompsonGas achieves a 60% lower cost per mile for its propane vehicles than diesel-powered models.With simplified maintenance requirements, the company estimates that its propane vehicles will last between 250,000 and 300,000 miles.