Global Events and Their Effect on Propane Markets

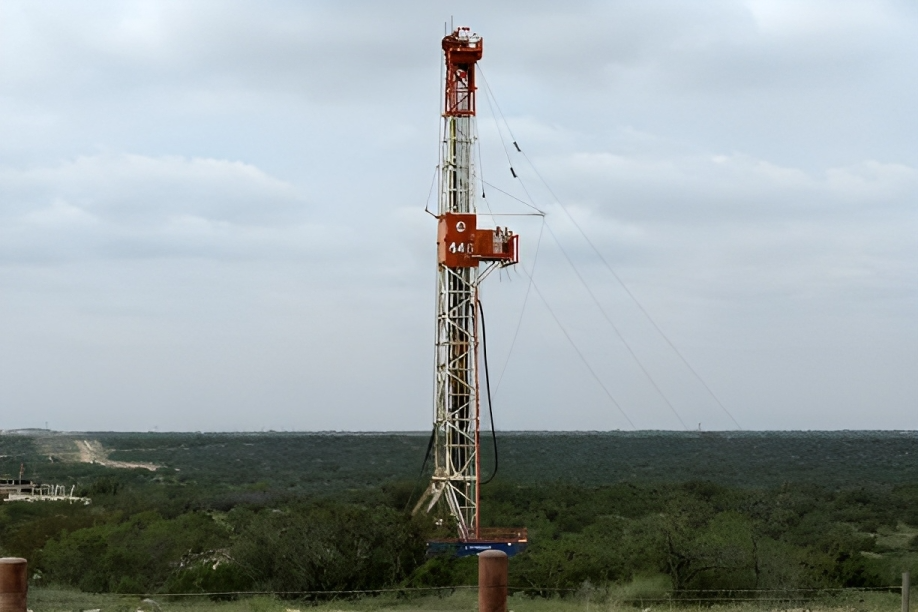

Navigating Propane Prices and Supply Amidst Global Changes Like many other industries, the propane market is significantly influenced by global events. From geopolitical tensions to environmental policies, various factors play a role in shaping propane prices and availability. Let’s explore how these global occurrences impact the propane industry and what it means for suppliers and… Continue reading Global Events and Their Effect on Propane Markets