Revolutionizing Safety Relief Valves: Enhanced Efficiency and Environmental Benefits

Safety relief valves are pivotal in upholding the safety and integrity of containers that handle potentially hazardous substances. Recent advancements in relief valve design, particularly the introduction of cartridge-style relief valves, have ushered in significant improvements in efficiency, safety, and environmental impact.

Traditional Relief Valve Operation

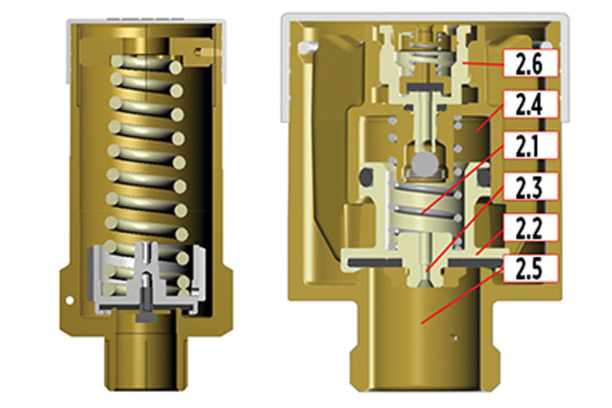

Traditionally, safety relief valves have operated by employing a spring mechanism. When the pressure within a container exceeds the force exerted by the spring, the valve opens to release excess pressure. Subsequently, as the pressure inside the container decreases to a safe level, the spring forces the valve to close, restoring equilibrium. This mechanism has formed the basis of safety relief valve operation for decades.

Cartridge-Style Relief Valve

The emergence of cartridge-style relief valves has marked a paradigm shift in pressure relief technology. Unlike their conventional counterparts, these valves feature a replaceable cartridge design that eliminates the need for complex procedures such as evacuating and depressurizing containers during relief valve renewal.

1. Operational Flexibility and Safety Enhancement

Cartridge-style valves bring operational flexibility to the forefront. Users can seamlessly replace the cartridge without disrupting the container’s pressurization. This not only eliminates the requirement for specialized skills but also significantly reduces downtime, all the while mitigating risks associated with manual interventions. These valves contribute to enhanced safety protocols by simplifying the maintenance process.

2. Balanced Force Distribution for Enhanced Performance

A notable feature of cartridge-style relief valves is their emphasis on balanced force distribution within containers. Unlike traditional valves that often rely on contrast springs to manage pressure, these valves achieve equilibrium through a small hole connecting the sliding chamber of the main piston with the container’s internal side. This design ensures efficient pressure management without placing undue stress on internal seals.

3. Precision Opening and Closing Mechanism

The opening and closing mechanism of cartridge-style valves is intricately linked to the pressure management system. A small valve controls the opening pressure of the main piston and the valve discharging pressure. Activation of this valve lowers the pressure in the chamber, causing the main piston to open. Upon the container pressure reaching a specified level, the valve closes, and the main piston follows suit due to pressure equalization. This dynamic mechanism ensures accurate pressure control and swift response to changing conditions.

4. Safety and Environmental Benefits

A primary advantage of cartridge-style relief valves lies in their ability to streamline maintenance procedures. Allowing cartridge replacement without evacuations or depressurization significantly minimizes safety and environmental risks. The conventional method of flaring during maintenance is not only risky but can also be time-consuming. The cartridge-style valve eliminates these challenges, promoting a safer and environmentally friendly approach to relief valve renewal.

5. Operational Continuity and Cost Savings

Reduced maintenance downtime leads to substantial cost savings for industries reliant on safety relief valves. Swift renewal processes minimize operational disruptions, enhancing efficiency and productivity. These benefits encompass not only financial savings but also improved safety protocols, reduced environmental impact, and enhanced operational continuity.

6. Industries and Applications

The benefits of cartridge-style relief valves extend across various industries. From oil and gas to chemical manufacturing, these valves offer a versatile solution for managing pressure in a wide range of containers. The ability to replace cartridges without interrupting operations is particularly advantageous in industries where downtime translates to significant financial losses.

7. Technology Evolution and Future Implications

The introduction of cartridge-style relief valves marks a significant milestone in the evolution of pressure relief technology. As industries continue to prioritize safety, efficiency, and environmental impact, further advancements in relief valve design are likely to emerge. The integration of digital monitoring systems and predictive maintenance technologies could further enhance the performance and effectiveness of safety relief valves.