Pressure Testing Propane Systems: Adapting to New Safety Standards

Ensuring the safety and reliability of propane systems begins with proper pressure testing. Recent updates to industry standards emphasize the importance of these tests in preventing leaks and safeguarding property. For propane businesses, adapting to these changes is essential for compliance and customer satisfaction.

Why Pressure Testing Is Critical

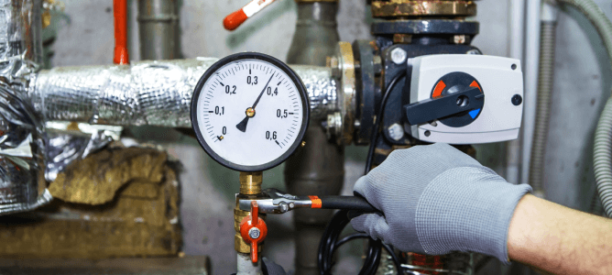

Pressure testing is the cornerstone of safety for propane piping systems. It helps identify weaknesses or leaks that could pose risks to customers and businesses alike. By implementing thorough testing procedures, propane providers can minimize hazards and maintain high service standards.

Recent Changes in Testing Requirements

The latest updates to pressure testing procedures introduce higher safety benchmarks. These changes aim to enhance reliability and protect against failures. They include:

✔︎ Higher test pressures for modern systems

✔︎ Longer monitoring times to detect minor leaks

✔︎ Greater emphasis on detailed test documentation

Preparing Your Team for the New Standards

To stay ahead of regulatory changes, propane businesses should focus on:

Training: Ensure that technicians are familiar with updated testing protocols.

Equipment Upgrades: Invest in modern tools for precise measurements and detection.

Pre-Testing Inspections: Check for visible issues before conducting pressure tests.

Building Customer Confidence

By adhering to the latest pressure testing standards, propane businesses demonstrate their commitment to safety and professionalism. Customers value providers who take proactive steps to protect their systems and reduce risks. This consumer confidence could very well result in positive referrals, repeat business, and long-term contracts.

If your propane business isn’t making a priority of pressure testing, why not? No pressure (pun intended), but you should add that to your company’s list of safety protocols today.