Businesses Gain Greater Flexibility With Propane Conversion Kits

As energy demands grow and costs continue to rise, many businesses and individuals are searching for smarter ways to power their equipment and vehicles. Propane has become a popular choice because it is dependable, cleaner-burning than many traditional fuels, and often more affordable. One of the key tools that makes switching to propane possible is the propane conversion kit. These kits allow engines originally built for gasoline or diesel to run on propane, giving users flexibility, savings, and new opportunities for efficiency.

Propane conversion kits are not new, but their importance is growing as more people look for reliable alternatives to traditional fuels. Understanding how these kits work and why they matter can help you see why they are becoming a valuable part of energy planning in various industries ranging from agriculture to transportation.

How Conversion Kits Work

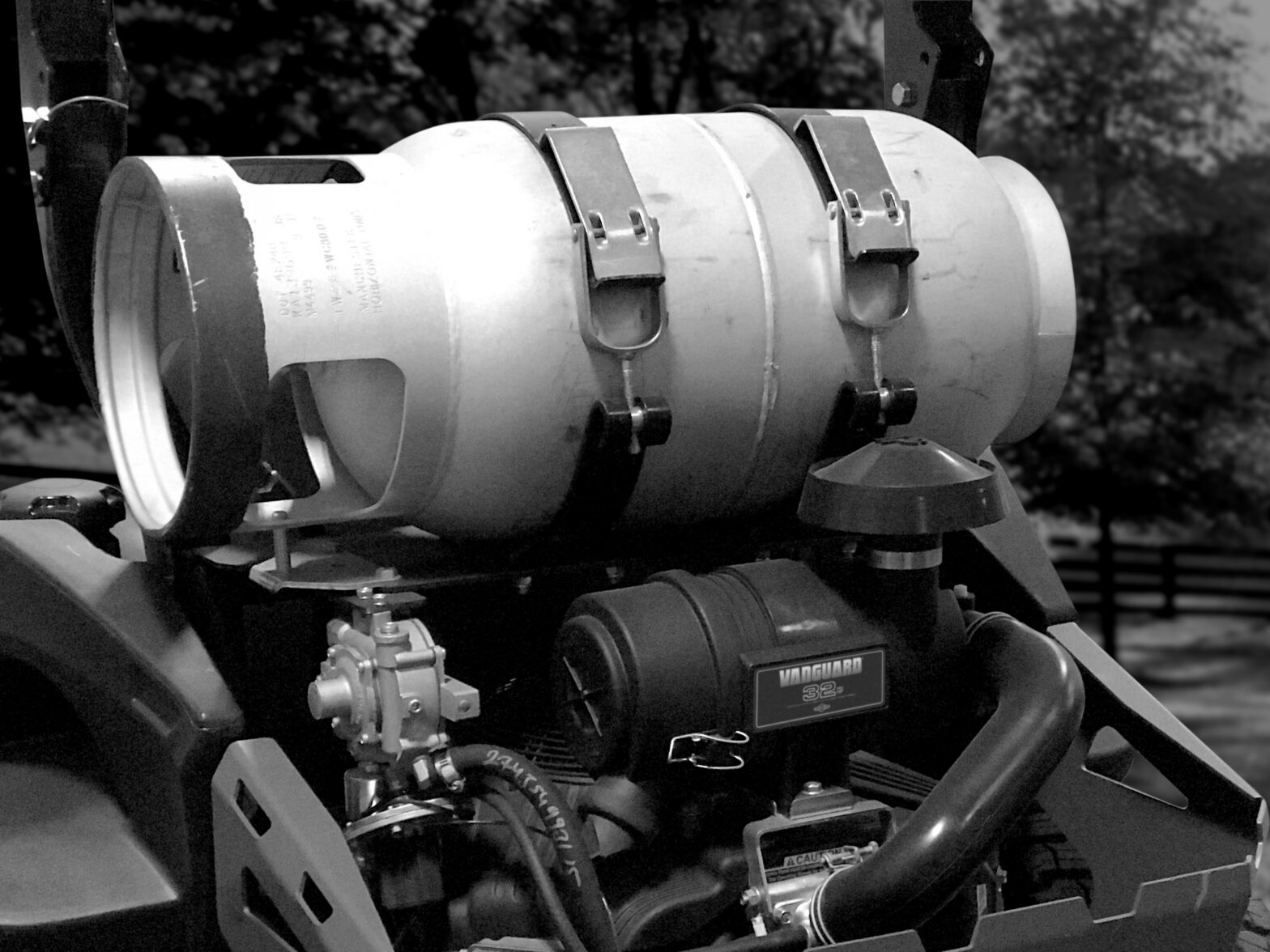

A propane conversion kit is designed to modify an existing engine so it can run on propane instead of gasoline or diesel. The kit typically includes components that control fuel delivery, adjust the air-to-fuel ratio, and ensure the engine performs smoothly with propane. While the basic engine remains the same; the fuel system is simply adapted to handle propane safely and effectively.

Why Propane is an Attractive Choice

There are many reasons people consider converting engines to propane. Propane often costs less than gasoline or diesel, which helps lower fuel expenses. It also burns cleaner, producing fewer emissions that can build up in engines and the environment. This leads to less wear and tear, fewer maintenance issues, and a longer lifespan for the equipment involved. For propane businesses, these key advantages add up to desirable savings and reliability that can be passed on to the customer.

Flexibility and Control of Fuel Supply

One of propane’s many strengths is the ability to store it on-site in tanks, giving users direct control over their supply. When engines are converted to propane, they are no longer dependent solely on fuel stations or the grid. This independence makes propane-powered equipment more reliable, especially in areas where access to gasoline or diesel fuel may be limited or disrupted.

Practical Considerations for Conversion

While propane conversion kits provide many benefits, proper installation and training are important. Engines must be converted carefully to ensure safety and efficiency. Maintenance routines may also differ slightly from gasoline or diesel engines. When done correctly, however, the conversion process allows users to get the most out of their equipment while enjoying the various advantages of propane.

The Growing Role of Conversion Kits

As industries look for cost savings and cleaner operations, propane conversion kits are becoming more common. They give businesses a resourceful way to adapt existing equipment instead of buying new machines, making the switch to propane more affordable and practical. This is especially appealing in industries where large fleets of engines are already in use.

Business Implications

For propane businesses, conversion kits represent more than just a product to sell; they represent a great business opportunity. By offering continued guidance, fuel, and support for customers interested in propane conversions, companies can build stronger client relationships and expand their services. Helping customers transition to propane not only grows demand but also positions propane businesses as problem-solvers in a competitive energy market. As more industries look for dependable and cost-effective energy options, propane conversion kits open the door to lasting partnerships and continued growth.